The company OOO “AKS SPLAV” purchases motor aluminum scrap.

Purchase of motor scrap aluminum

DSTU3211:2009/GOST1639:2009

| №p/p | Name | |

| 1 | Aluminum 13 | Aluminum casting scrap (motor scrap) |

| 2 | Aluminum 15 | Piston scrap disassembled without supports, bearings, shafts, rings, etc. |

| 3 | Aluminum 16 | Piston scrap, undisassembled |

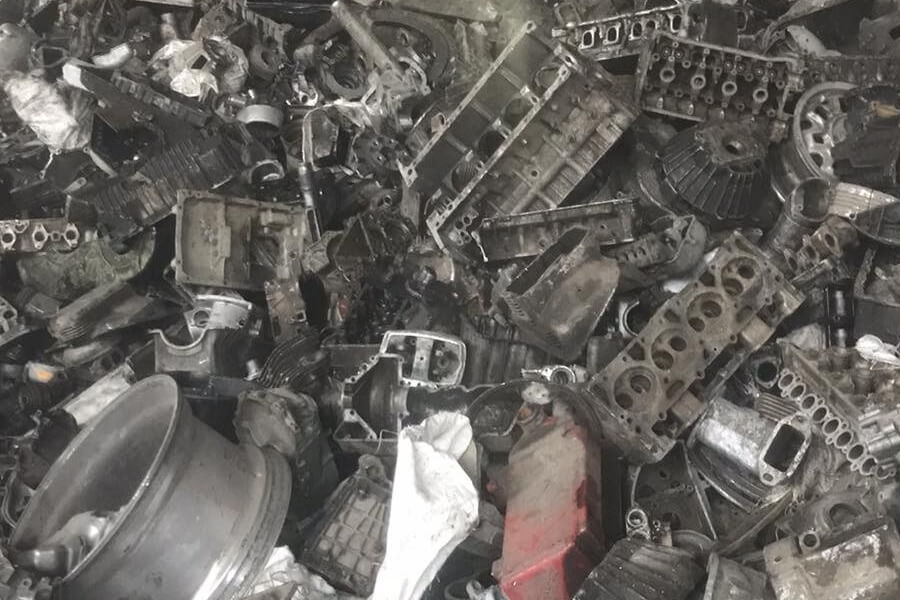

Aluminum engine scrap is waste and remnants of aluminum parts that were used in various engines, most often automobile or industrial equipment. Buying aluminum engine scrap is an important part of recycling, which allows you to effectively use metals and reduce the cost of extracting new resources. In this section, we will consider the features of buying aluminum engine scrap, its cost, the benefits of recycling and the rules for delivery.

Aluminum engine scrap is waste and remnants of aluminum parts that were used in various engines, most often automobile or industrial equipment. Buying aluminum engine scrap is an important part of recycling, which allows you to effectively use metals and reduce the cost of extracting new resources. In this section, we will consider the features of buying aluminum engine scrap, its cost, the benefits of recycling and the rules for delivery.

Aluminum engine scrap includes metal elements that make up various engine parts, such as housings, cylinder blocks, valves, and other components. These components are often subject to mechanical wear and tear, and once they are no longer usable, they can be recycled. Aluminum used in engine parts is often alloyed with increased strength, making them valuable for recycling.

Why is aluminum motor scrap being bought?

The purchase of aluminum motor scrap has several important goals that contribute to the economy and sustainable development:

- Aluminum recycling: recycling aluminum in motor scrap significantly reduces the need for the extraction of new resources, saving natural resources.

- Cost reduction: using recycled aluminum, it is possible to significantly reduce the cost of producing new products.

- Environmental effect: recycling aluminum reduces carbon dioxide emissions and reduces the amount of waste in landfills.

- Obtaining high-quality material: due to the high quality of aluminum alloys used in engines, recycled metal can be used to produce new high-quality products.

The process of handing over aluminum motor scrap

The process of handing over aluminum motor scrap includes several stages that must be completed before it can be recycled:

- Sorting: first, the scrap must be sorted, separating pure aluminum and its alloys from other metals and contaminants.

- Transportation: the scrap is delivered to collection points or to recycling plants for further processing.

- Value assessment: at collection points, the quality and value of aluminum motor scrap is assessed based on the composition and condition of the material.

- Recycling: the aluminum is melted, cleaned of impurities, and used to produce new parts or other products.

Advantages of handing over aluminum motor scrap

There are several significant advantages to handing in scrap aluminum from motor vehicles:

- Cost savings: recycled aluminum is often cheaper than buying new, which allows you to save on material costs.

- Environmental benefits: recycling helps reduce the burden on nature, as it reduces the volume of garbage and pollution.

- High cost of metal: aluminum is one of the most expensive metals on the secondary market, which makes its recycling profitable.

- Sustainability of production: recycling aluminum helps create a closed production cycle and reduces dependence on primary resources.

Motor aluminum scrap price per kg

The price per kg of motor aluminum scrap also depends on many factors.

The average price may vary depending on:

- Metal purity: the fewer impurities in the scrap, the higher its price.

- Aluminum alloy type: some aluminum alloys have a higher value than others.

- Quantity: large batches of scrap may be sold at a better price.

- Market: pricing policy may vary depending on the market demand for aluminum and the metallurgical industry.

GOST and standards for motor aluminum scrap

Motor aluminum scrap is subject to certain standards, such as GOST, which regulate its quality and recycling. According to the standards, scrap must be cleaned of foreign impurities and contaminants. The use of these standards ensures that recycled aluminum meets all quality and safety requirements, and also avoids problems when using it in the further production process.

Application of aluminum scrap motors

Aluminum scrap motors after recycling are used in various industries:

- Automotive industry: aluminum is used to produce car parts, such as body panels, engines, gearboxes.

- Mechanical engineering: recycled aluminum is used to produce various structural elements.

- Energy and construction industry: aluminum is used to create lightweight and durable structures.

- Production of building materials: recycled aluminum is used in building materials and for the production of aluminum structures.

Purchasing aluminum scrap is a profitable operation for both processors and those looking for a way to get rid of old parts and get money for them. Recycling aluminum parts from engines helps save resources, reduce material costs and reduce environmental pollution. At the same time, due to the high cost of aluminum on the secondary market, this is beneficial for all participants in the process.