Ferrotitanium

Ferrotitanium: description, production and application

Table 1

|

Brand |

Mass fraction,% |

|||||

|

Titanium

|

Aluminium

|

Silicon | Carbon | Phosphorus |

Sulfur |

|

|

No more |

||||||

|

FTi35S5 |

28-40 | 8 | 5 | 0.2 | 0.04 |

0.04 |

|

FTi35S7 |

28-40 | 9 | 7 | 0.2 | 0.07 |

0.05 |

|

FTi35S8 |

28-40 | 14 | 8 | 0.2 | 0.07 |

0.07 |

Table 2

| Brand | Mass fraction,% | |||||||

| Copper

|

Vanadium | Molybdenum | Zirconium | Tin | Manganese | Chrome | Iron | |

| No more | ||||||||

| FTi35S5 | 2 | 0.4 | 0.2 | 0.2 | 0.04 | – | – | All the rest |

| FTi35S7 | 2 | 0.8 | 0.5 | 0.2 | 0.05 | – | – | All the rest |

| FTi35S8 | 3 | 1 | 1 | 0.7 | 0.08 | – | – | All the rest |

Ferrosilicocyrconium

| Brand | Mass fraction,% | ||||||||||

| Zirconium | Silicon | Aluminum | Titanium | Phosphorus | Sulfur | Carbon | Nickel | Copper | Iron | ||

| No more | |||||||||||

| FSC |

14-25

|

6-16 | 6-15 | 2 | 0.1 | 0.05 | 0.2 | 0.015 | 2 | All the rest | |

| Separate elements are coordinated with the consumer. | |||||||||||

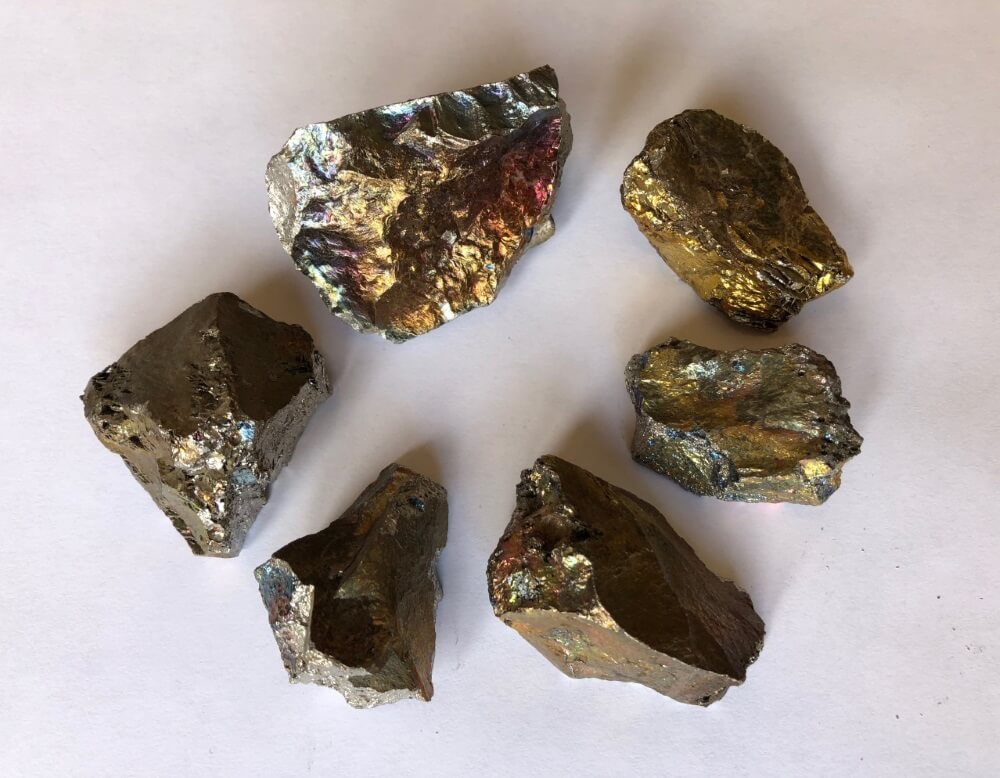

Ferrotitanium is an alloy of titanium and iron that is used in the metallurgical industry to alloy various alloys. It is an important component in the production of titanium, stainless steel and other alloys, which improves mechanical properties and corrosion resistance. Due to its unique ability to improve the characteristics of alloys, ferrotitanium has found wide application in various industries, from aviation to mechanical engineering.

What is ferrotitanium?

Ferrotitanium is an alloy consisting of titanium and iron, which is used in metallurgy to create high-quality steels and alloys. It is used to alloy steel alloys to increase their strength, corrosion resistance and heat resistance. It is an important component for the production of titanium, which has a number of advantages, such as high heat resistance, strength and resistance to aggressive environments.

Chemical composition of ferrotitanium

The chemical composition of ferrotitanium depends on its brand and purpose, but the main component is titanium, which is alloyed with iron. In different grades of ferrotitanium, the titanium content can vary from 10 to 35%, with iron making up the rest of the composition. In addition, other elements such as carbon, silicon, manganese can be added to improve certain properties of the alloy.

Example of ferrotitanium compositions:

- Ferrotitanium FTI35 — the titanium content in this alloy is about 35%.

- Ferrotitanium FTI35 S8 2 — a special grade of ferrotitanium with additional characteristics for use in difficult conditions.

Ferrotitanium production

Ferrotitanium production includes several stages, from mining and preparation of raw materials to smelting and alloying. The production process involves high-tech smelting furnaces, which allow you to achieve the required temperature for fusion of titanium and iron.

The main stages of ferrotitanium production:

- Preparation of raw materials – iron and titanium are purified from impurities and prepared for smelting.

- Smelting – the metal melts in furnaces at high temperatures, and ferrotitanium is formed.

- Alloying – other elements, such as carbon and silicon, are added to the melt to improve the mechanical and chemical properties of the alloy.

- Cooling and molding – after cooling, ferrotitanium is formed into ingots or other necessary forms, ready for use in industry.

Application of ferrotitanium

Ferrotitanium is used in various industries, primarily in metallurgy and mechanical engineering.

Its main areas of application are:

- Steel production — ferrotitanium is used to alloy steels, increasing their strength and heat resistance.

- Titanium alloy production — ferrotitanium is the main raw material for obtaining titanium alloys, which are used in aircraft construction, the space industry, and in the production of high-tech parts.

- Aviation and space industry — high-strength and heat-resistant titanium obtained using ferrotitanium are used in aircraft designs.

- Mechanical engineering — ferrotitanium improves the characteristics of metals used in the production of parts subject to high loads and temperature effects.

- Chemical industry — ferrotitanium is used to produce alloys resistant to aggressive chemicals.

Ferrotitanium GOST

Ferrotitanium GOST is a standard that regulates the quality of ferrotitanium in Ukraine. The standards include requirements for chemical composition, physical and mechanical properties, as well as quality control methods. These GOSTs help ensure that products comply with established requirements and guarantee stable quality of materials for industrial use.

Ferrotitanium Price

The price of ferrotitanium depends on many factors, including its brand, composition, and purchase volume.

To estimate the cost of ferrotitanium, the following points should be taken into account:

- Ferrotitanium brand – for example, ferrotitanium fti35 will cost more than less concentrated brands due to its high titanium content.

- Purchase volume – wholesale purchases are usually cheaper.

- Manufacturer – the cost may vary depending on the region and brand of the manufacturer.

- Price per kg – usually the price of ferrotitanium is indicated per kilogram, and it may change depending on market conditions.

The average retail price of ferrotitanium may vary depending on the quality and brand. You can order ferrotitanium directly from manufacturers or through suppliers who offer different delivery options.

Ferrotitanium delivery

Ferrotitanium delivery depends on the order volume and the location of the buyer. For large quantities, ferrotitanium is often delivered by rail, and for small quantities – by road. An important aspect is packaging and protecting the goods from damage during transportation.

Ferrotitanium price per kg

Ferrotitanium price per kg varies depending on the quality of the alloy and its grade. For example, ferrotitanium fti35 may have a price that differs from cheaper grades. It is also important to take into account the exchange rate, since the price of raw materials for the production of ferrotitanium may change depending on the market situation.