AKS splav LLC purchases non-ferrous metal scrap.

Purchase of aluminum raw materials for production

Purchase of aluminum scrap

DSTU3211: 2009 / GOST1639: 2009

|

№ |

Name |

|

|

1 |

Aluminum 2 |

Aluminum scrap non-ligated: electrotechnical products |

|

2 |

Aluminum 4 |

Scrap aluminum alloys with a low content of copper |

|

3 |

Aluminum 6 |

Waste aluminum alloys with low zinc content and a high content of copper |

|

4 |

Aluminum 7 |

Aircraft scrap deformable aluminum alloys with low zinc content |

|

5 |

Aluminum 8 |

Aluminum rolling and casting waste with high magnesium content |

|

6 |

Aluminum 9 |

Scrap of deformable and casting aluminum alloys with high magnesium content |

|

7 |

Aluminum 10 |

Waste of aluminum rolling products with high zinc content |

|

8 |

Aluminum 11 |

Aircraft scrap deformable aluminum alloys with high zinc content |

|

9 |

Aluminum 12 |

Aluminum casting waste: defective items |

|

10 |

Aluminum 13 |

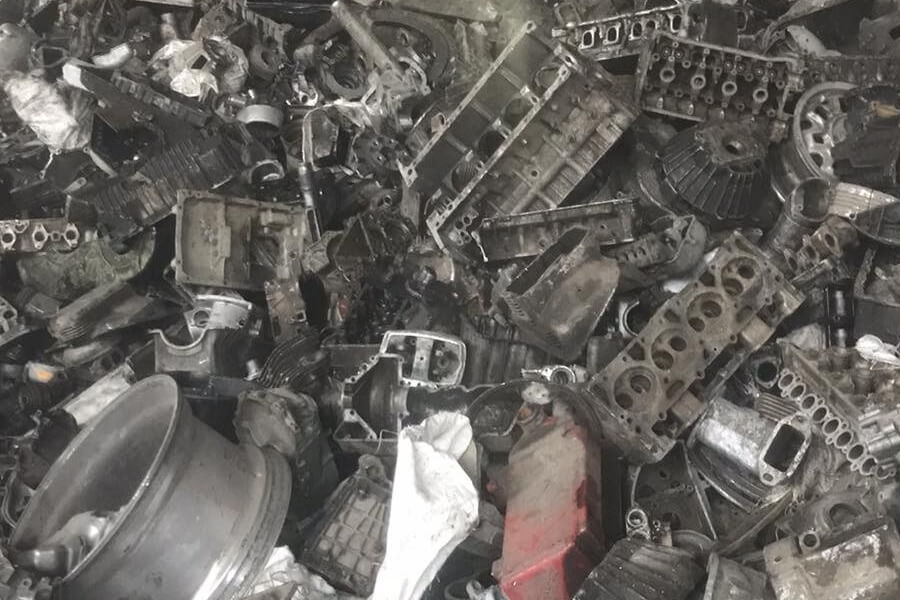

Scrap of aluminum casting (motor scrap) |

|

11 |

Aluminum 14 |

Mixed aluminum casting scrap, aluminum – silicon |

|

12 |

Aluminum 15 |

Scrap of pistons disassembled without stands, bearings, shafts, rings, etc. |

|

13 |

Aluminum 16 |

Not disassembled scrap pistons |

|

14 |

Aluminum 17 |

Aluminum casting scrap and waste with nickel content |

|

15 |

Aluminum 18 |

Aircraft aluminum disassembled, casting alloys |

|

16 |

Aluminum 19 |

Scrap aluminum crushed. Casting and deformable alloys |

|

17 |

Aluminum 26 |

Household scrap with a specific chemical composition |

|

18 |

Aluminum 27 |

Previously molten scrap ingots with known chemical composition |

|

19 |

Aluminum 28 |

Packs or briquettes from aluminum cans |

|

20 |

Aluminum 29 |

Aircraft scrap, sheet, disassembled from deformable alloys |

|

21 |

Aluminum 30 |

Wastes from the production of aluminum cans |

|

22 |

Aluminum 31 |

Scrap beverage cans |

|

23 |

Aluminum 32 |

Crushed scrap aluminum beverage cans magnetized |

|

24 |

Aluminum 20 |

Clean loose aluminum shavings, sorted by aluminum alloy groups silicon, foundry or deformable |

|

25 |

Aluminum 21 |

Loose aluminum shavings mixed |

|

26 |

Aluminum 22 |

Aluminum bindweed shavings mixed |

Aluminum is one of the most sought-after metals in various industries, including the automotive, aircraft, building materials, and electronics industries. For many companies, purchasing aluminum raw materials is an important part of the production process. One source of raw materials is aluminum scrap, which goes through a recycling process to create new materials. In this text, we will consider what buying aluminum scrap is, how this material is processed, and what factors affect its cost.

What is aluminum scrap?

Aluminum scrap is scrap metal consisting of aluminum or its alloys that can no longer be used in its original form and is subject to recycling. Aluminum scrap can include old metal products, components from cars, building materials, and waste generated during the manufacturing process.

The main types of aluminum scrap:

- Electrical aluminum scrap is waste obtained during the disassembly of electrical devices and cables containing aluminum.

- Aluminum scrap and waste are old parts and products that have become unusable for various reasons.

- Aluminum mix is a mixture of different types of scrap that will be recycled to create new aluminum products.

Aluminum Scrap Recycling Process

Aluminum scrap recycling involves collecting, cleaning and then melting it, resulting in primary aluminum or aluminum alloys.

This process involves several steps:

- Collection and sorting – scrap is collected from various sources, then sorted by type and category.

- Refining – contaminants and impurities are removed from the aluminum scrap.

- Smelting – after cleaning, the aluminum is melted in furnaces, where a melt is formed.

- Forming and cooling – the molten aluminum is poured into molds, forming ingots, which are then sent for further processing or for sale.

The process of recycling aluminum scrap reduces the need for new resource extraction, as well as the amount of waste, which makes it important for the sustainable development of the industry.

Purchase of aluminum scrap

Purchase of aluminum scrap is the process of purchasing aluminum scrap metal of various origins for the purpose of its processing.

Important aspects of buying include:

- Sorting – aluminum scrap is often divided into several categories, such as pure aluminum, alloys, castings, and other types. Each of these has its own price.

- Price – the cost of aluminum scrap can vary depending on the quality, composition, and condition of the metal.

- Purchase frequency – aluminum recycling companies often need a constant supply of scrap to maintain continuous production.

Cost and price of aluminum scrap

The cost of aluminum scrap directly depends on a number of factors:

- Purity and composition – the purer the aluminum and the fewer impurities, the higher its price.

- Type of aluminum – the cost may vary depending on the type of scrap. For example, electrical aluminum scrap may have its own price, different from ordinary aluminum scrap.

- Volume – large batches of scrap can be sold at more favorable prices for both parties.

- Scrap condition – if aluminum scrap is in good condition, its price will be higher than if it has significant damage.

For example, the acceptance of aluminum scrap may vary depending on its quality. While for purer aluminum or alloys, the price can be significantly higher.

Where to buy aluminum scrap

If you are looking for where to buy aluminum scrap, it is important to choose a reliable supplier who can provide high-quality material for recycling. Purchase of aluminum scrap can be carried out through specialized companies engaged in the collection and sale of scrap, as well as through online platforms.

It is important to consider the following factors:

- Quality check – before purchasing aluminum scrap, you should carefully check its composition and purity to avoid purchasing material with a large number of impurities.

- Delivery – many suppliers offer delivery services for aluminum scrap to the buyer’s enterprise.

- Price per kg – when purchasing scrap, it is important to consider the price per kilogram, which depends on market conditions.

Benefits of recycling aluminum scrap

Recycling aluminum scrap has several key benefits:

- Economic benefit – recycling aluminum reduces the cost of producing new metal and promotes the use of secondary materials.

- Environmental sustainability – recycling aluminum reduces waste and saves natural resources.

- Reduction in energy costs – recycling aluminum requires significantly less energy than mining and processing primary aluminum.

Thus, purchasing aluminum scrap for recycling is not only a profitable process for enterprises, but also an important step towards environmental sustainability.

Purchasing aluminum raw materials for production through the purchase of aluminum scrap is an important component of the metal processing industry. Aluminum scrap is a valuable resource for creating new products, and its recycling helps to significantly reduce costs while saving natural resources. When choosing a supplier for the purchase or sale of aluminum scrap, it is important to consider its price, quality, composition and delivery conditions.